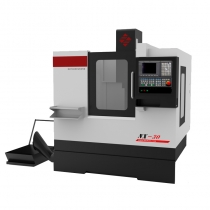

In this case, the mini milling machine NX30 is processing car valve body(material:lcast aluminium) of hiroshima aluminum industry. NX series milling machine is the upgraded product of TX series. It is thus of more rapid traverse, more elegant appearance. ……

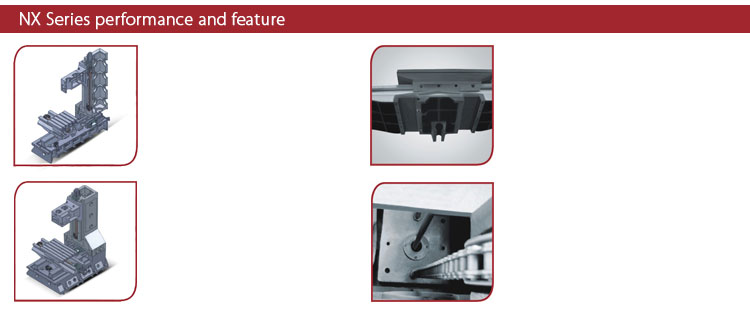

Main machine components have

adopted the structure of thermal

symmetry and thin-walled mainstock

with multi-layer ribs.

adopted the structure of thermal

symmetry and thin-walled mainstock

with multi-layer ribs.

The main base parts of machine are

made from high-grade high-quality

gray casting iron with quenching trement.

made from high-grade high-quality

gray casting iron with quenching trement.

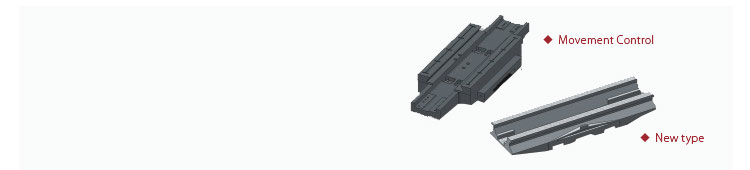

The use of special bearings on balls

crew with pre-pull treatment and laser

detective compensation.

crew with pre-pull treatment and laser

detective compensation.

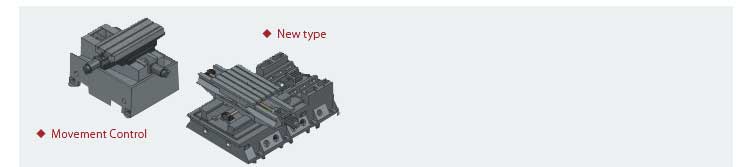

The adoption of balance weight block

with motion-based device has prevented

the spindle from vibration when moving.

with motion-based device has prevented

the spindle from vibration when moving.

The strength and rigidity of millling machine is improved

50%. The rigidity and stability of cutting feed are

enhanced so as to improve the machine processing

accuracy and using life.

50%. The rigidity and stability of cutting feed are

enhanced so as to improve the machine processing

accuracy and using life.

3 axis diven power is improved 30%. Spindle motor

driven power is improved more than 35%.

driven power is improved more than 35%.

Sliding saddle is optimized changed to a thin-walled

multi-ribbed box-type structure,making the sliding

saddle rigidity increased 50%.

multi-ribbed box-type structure,making the sliding

saddle rigidity increased 50%.

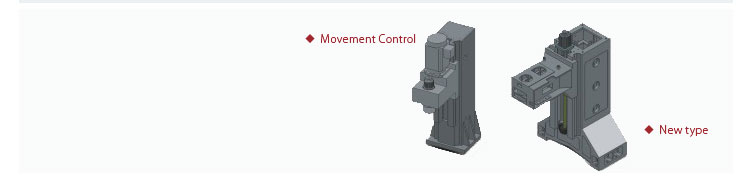

The column structure is changed into large span,

multi-ribs, thin-wall, box-shaped structure,the

rigidity is increased more than 60%.

multi-ribs, thin-wall, box-shaped structure,the

rigidity is increased more than 60%.

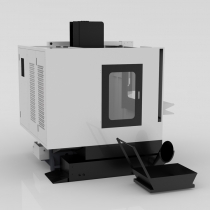

With this system, can get of the chips

efficiently, saving time much.

efficiently, saving time much.

Powerful chip washing system, it can

washing out the chips rapidly, avoid

the bad effect in machining.

washing out the chips rapidly, avoid

the bad effect in machining.

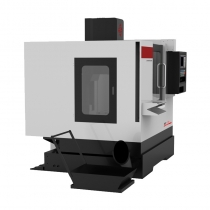

Standard Arm types A.T.C., more

rapidly than armless type in changing

tools, provide more efficiency in

machining.

rapidly than armless type in changing

tools, provide more efficiency in

machining.

Controller system up leveled, bigger

screen, more fit to human

engineering, more simple operation.

screen, more fit to human

engineering, more simple operation.

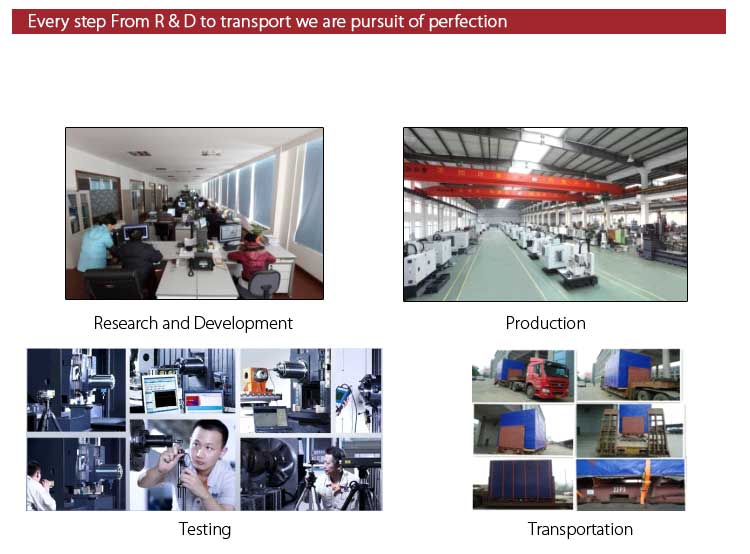

We have been insisting on the principle of customer first,from product research and development, procurement,production,

testing, packaging, transportation, we do every step the best.Give careful consideration to the needsand expectations of

customers.mini milling machine

testing, packaging, transportation, we do every step the best.Give careful consideration to the needsand expectations of

customers.mini milling machine

mini milling machine mini milling machine