Usually, there is no magazine in milling machine and only one in machining center. Obviously there is a finite limit to how many magazines can be "banked" for each machine tool and when a greater capacity is required this means using a different approach to tool delivery. Yet another chain-type method of tool carrying is that shown, where two magazines of tools are situated above and below one another and this application also lends itself to the "banking" technique, up to a maximum of three banks - giving a total of 270 tools.

As can be appreciated by observing the photograph, the range of tooling carried by such magazines is immense. The tooling inventory ranges from: small drills and endmills, to multi-spindle drilling heads,special-purpose tooling and large side-and-face cutters mounted upon stub arbors, to tool-sensing probes (i.e. touch-trigger probes). Clearly, when large diameter tools are held in their respective tool pockets, then the adjacent pocket either side of this tool must be left empty to avoid them fouling one another.

About cnc machining center. This fact can be appreciated by looking at the large diameter face mill shown in the bottom left-hand position of the lower magazine and at other positions in the photograph. Whenever a large tooling load is to be carried by a magazine it is important to "balance" the loads within it, by situating the heavy tools evenly throughout the tool pockets as this ensures that an out-of-balance effect is not created in any particular area of the chain.

What machine do your think is best suitable for installing two magazine? Just show your opinion.

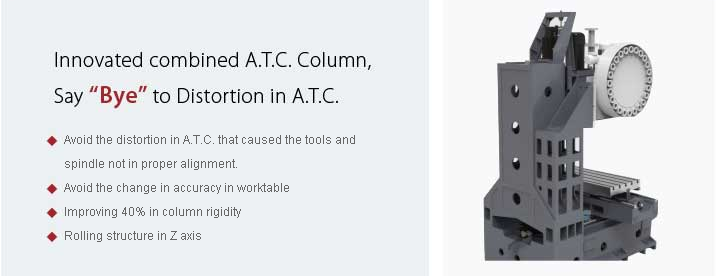

And here, we got a innovative one: combined A.T.C. column